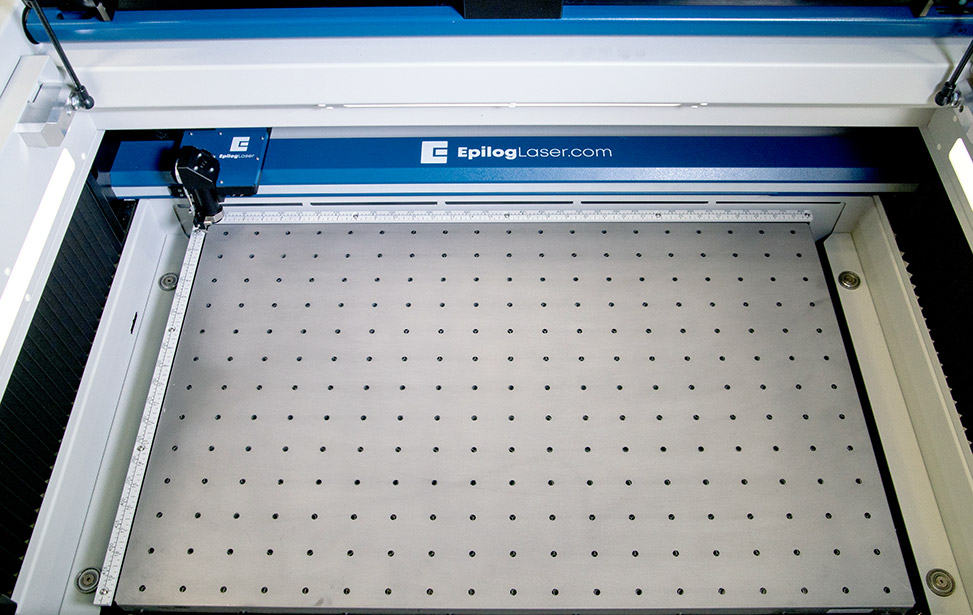

| Work Area | 24” x 24”

(610 x 610 mm) | 36” x 24”

(914 x 610 mm) | 48” x 36”

(1219 x 914 mm) |

| Maximum Z-Depth | 9” (228 mm) | 9” (228 mm) | 12.25” (311 mm) |

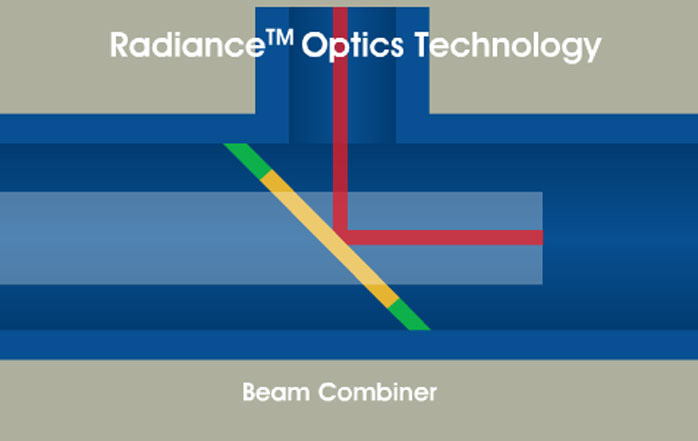

| Laser Tube Wattage | CO2 - 60 or 80 watts - air-cooled, metal/ceramic tube, 10.6 micrometers

Fiber - 30 or 50 watts - air-cooled, includes collimator, 1065 nm, Beam quality: M2 < 1.1

Dual Source - CO2 60 watts with Fiber 30 watts | CO2 - 60 or 80 watts - air-cooled, metal/ceramic tube, 10.6 micrometers

Dual Source - CO2 60 or 80 watts with Fiber 30 or 50 watts | CO2 - 80 or 120 watts - air-cooled, metal/ceramic tube, 10.6 micrometers

Dual Source - CO2 120 watts with Fiber 50 watts |

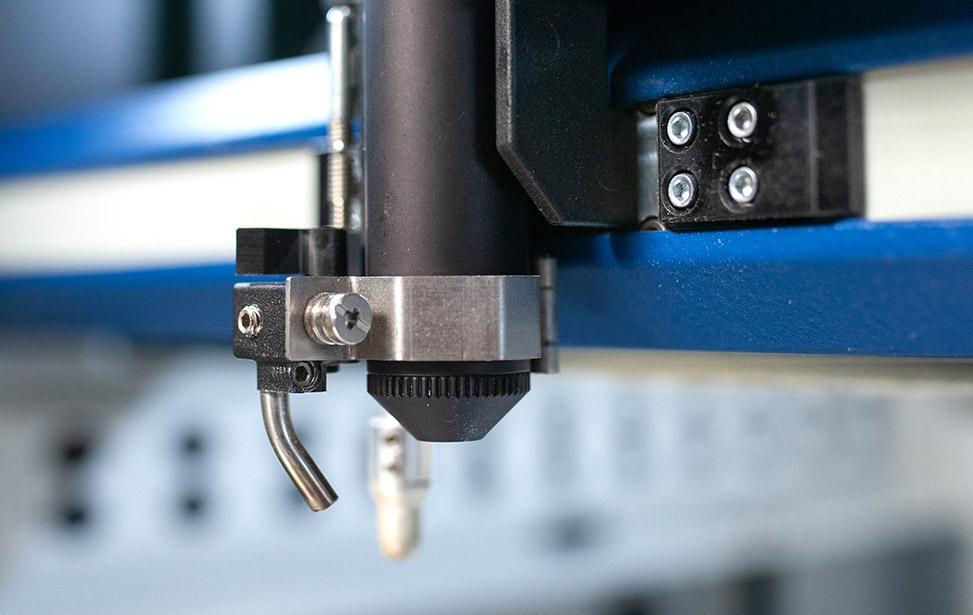

| Included Lens | 2" - CO2

3" - Fiber & Dual-Source |

| Optional Lenses | 1.5" (Pro 24 and 36 only) - CO2

4" - CO2 |

| Included Table | Vector Cutting Table (Grid-Style) | Task Plate |

| Air Assist Pump | Optional | Optional | Included |

| Status Light | Included | n/a |

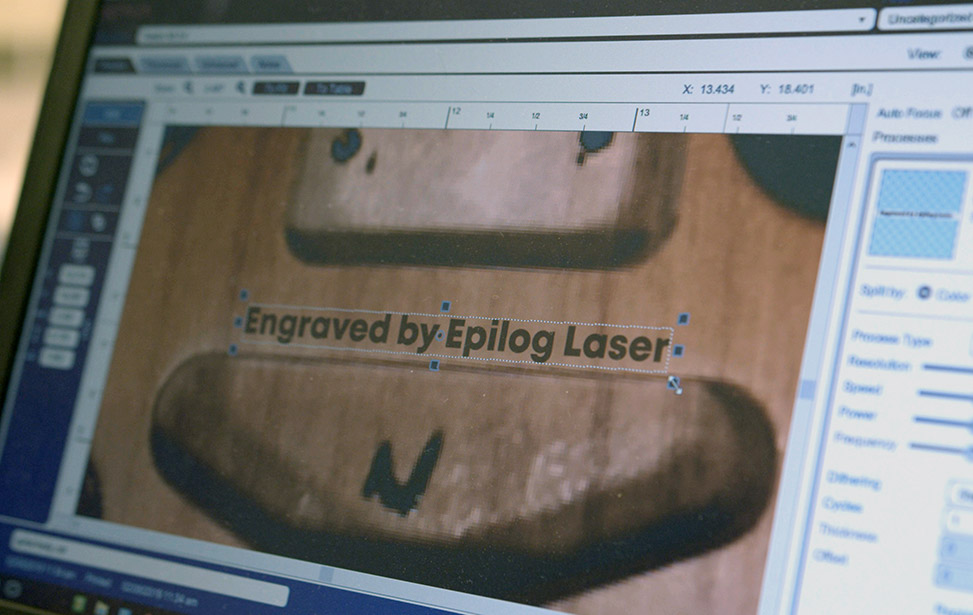

| Software | Epilog Laser Software Suite: Laser Dashboard™ & Epilog Job Manager™ |

| Memory | Multiple files up to 1 GB. Engrave any file size. |

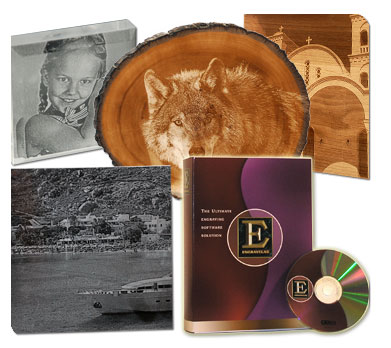

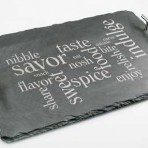

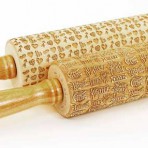

| Operating Modes | Optimized Raster, Vector, and Combined modes |

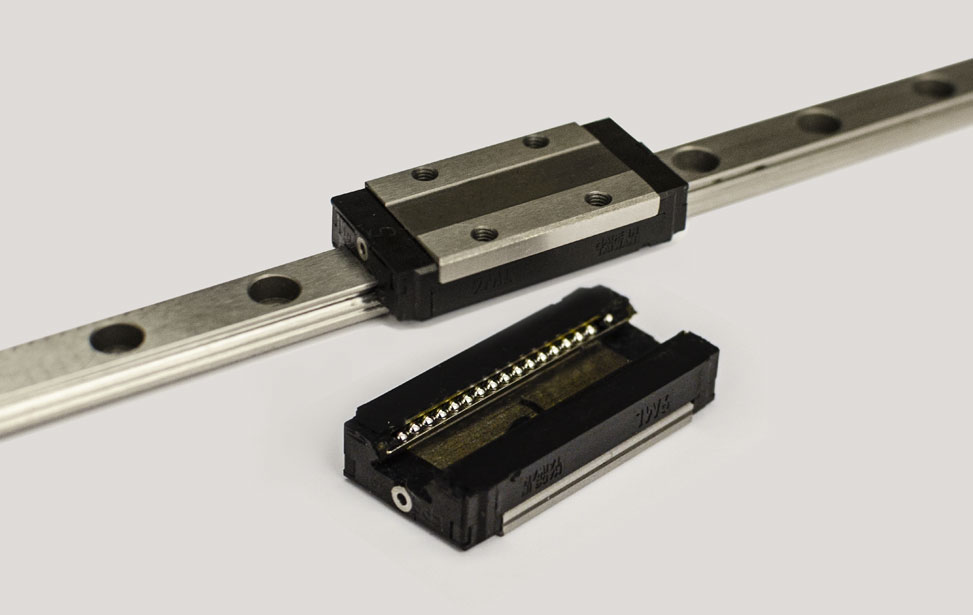

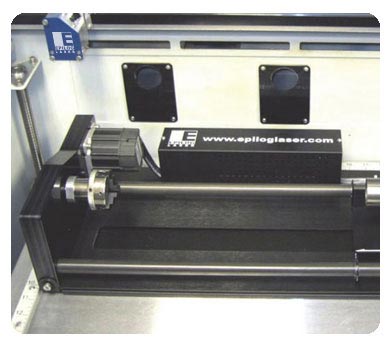

| Motion Control | High-speed, continuous-loop, brushless DC servo motors using rotary encoding technology for precise positioning |

| X-Axis Bearings | Ground & polished stainless steel, Teflon-coated, self-lubricating bearings. Dual blocks on X-axis for greater rigidity |

| Belts | Advanced B-style double-wide Kevlar precision drive belts. |

| Resolution | Fully-flexible and user-controlled from 75 – 1200 dpi |

| Speed and Power | 165 IPS (4.2m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. |

| Print Interface | USB, Wireless, and 10Base-T Ethernet. Windows 7/8/10 compatible. |

| Size (W x D x H) | 41.52” x 32.81” x 40.54"

1055 x 834 x 1029 mm | 53.52” x 32.81” x 40.54"

1359 x 834 x 1029 mm | 70.6” x 51.3" x 42.75"

1794 x 1304 x 1086 mm

Pedestal removed: 34” H (863 mm) |

| Weight | 240 lbs (108 kg) | 275 lbs (124 kg) | 650 lbs (295 kg) |

| Electrical | 110 to 240 volts, 50 or 60 Hz, single phase | 240 volts, 50 or 60 Hz, single phase |

| Ventilation | 350-400 CFM (595-680 m3/hr) external exhaust to outside or internal filtration unit required. One output port, 4" (102 mm) diameter | Three total ports. Two upper exhaust ports, one lower vacuum table port. Total 735 CFM required. All ports 4” (102mm). |

| Safety | Class 2 Laser Product – 1 mW CW Maximum 600 – 700 nm |